Diecasting is now an integral aspect of the manufacturing industry in Malaysia which plays an important part in the production of high-quality metal parts for a variety of industries. Diecasting, which entails pushing molten metal through the mold cavity with intense pressure, is well-known for its precision and capacity to make complex forms. Diecasting in Malaysia has significantly grown recently due to Malaysia’s strategically located geographical location, skilled workforce and dedication to technology advancement. In the process, Malaysia is now the center of diecasting in Southeast Asia, catering to sectors like electronics, automobiles and consumer products.

One of the primary factors driving the rise of diecasting Malaysia is its use for the automotive industry. The auto industry is heavily dependent on diecasting in order to create sturdy, lightweight components such as motor blocks, transmission case and other structural parts. They are crucial in reducing the weight of vehicles as well as improving fuel efficiency while ensuring safety and strength. In the global market, demand for green and fuel efficient cars increases, Malaysian diecasting companies are ready to take advantage of this trend, by creating new solutions to are able to meet the demands of today’s market. Malaysia’s auto manufacturing industry has been collaborating with multinational companies, further expanding its capabilities in diecasting.

The electronics sector is booming in Malaysia has also benefited greatly from diecasting techniques. Being a top exporter of electronics worldwide, Malaysia produces a wide assortment of items that range from semiconductors to consumer electronic products. Diecasting plays a crucial role when it comes to creating housings made of metal and parts for the devices, as it ensures durability as well as precision of the finished item. Due to the rapid growth of smart phones and devices connected to the Internet of Things (IoT) demands for precise diecast components has grown substantially. Malaysian producers are able to meet this need by implementing sophisticated diecasting processes, like robotics and automation in order to produce top-quality parts at a reasonable cost.

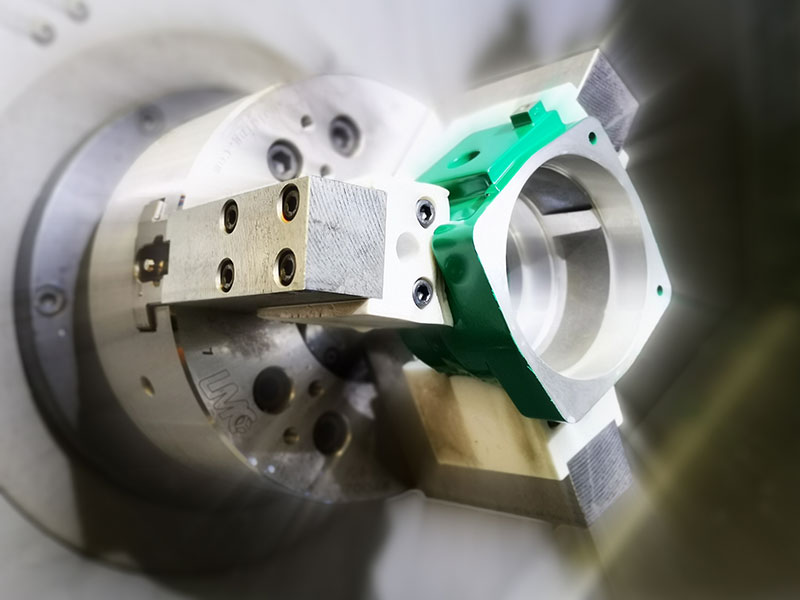

The technological advancements in diecasting have contributed to propelling Malaysia’s industry of diecasting up to new levels. Malaysian diecasting firms are investing in cutting-edge equipment and machinery like high-pressure casting machines as well as Computer-aided Design (CAD) software to enhance efficiency and improve accuracy. The integration of technology can help manufacturers reduce the time of production, reduce the amount of waste and create highly precise and complex components. Furthermore, advances in materials science have led to the creation of light alloys such as magnesium and aluminum which further enhances the efficiency and durability of diecast components. For more information please visit here Senadiecasting

The skilled Malaysian workforce is a important factor that is driving the development of the diecasting business. It has placed a large importance on vocational and education training to ensure that employees are trained with the required skills needed to use cutting-edge diecasting equipment and techniques. The local universities and technical institutions offer specialization that focus on manufacturing and engineering which creates a pipeline of potential talent to industries. In addition the government has launched programs to promote study and development in diecasting and encourages innovation while making sure that Malaysian enterprises are competitive on the international level.

While Malaysia’s diecasting industry grows and expand, the country is paying a lot of attention to the environment and sustainability. Diecasting is an extremely efficient method that produces minimal pollution, while the usage of recyclable materials for example, aluminum, decreases the impact on the environment. Malaysian firms are adopting eco-friendly manufacturing techniques, like efficient machinery that is energy efficient and closed loop recycling processes, which reduce the carbon footprint of their operations. The efforts are in line with international trends towards sustainable manufacturing, and place Malaysia as a leading country in green diecasting technologies.

In the end, Malaysia’s diecasting business is rapidly growing and is driven by its use to key sectors like electronic and automotive as well as technological advances and the skilled workforce. Malaysia’s dedication to the environment and sustainable practices has helped position Malaysia as an important participant in the worldwide diecasting industry. The demand for lighter sturdy, robust and environmentally sustainable components grows, Malaysia is well-positioned to fulfill these demands, establishing its status as a key centre for diecasting across the region. Diecasting’s future in Malaysia is bright with an ongoing investing in technology, people and sustainable methods ensuring the long-term viability of diecasting.

+ There are no comments

Add yours